Navigating the complexities of tractor-trailer weight limits can be challenging, but understanding maximum axle weights is crucial for both legal compliance and safety. This guide provides clear, actionable steps to help drivers, trucking companies, and regulators ensure their operations remain within legal boundaries. For more information on larger sleeper cabs, check out this resource.

Understanding Axle Weight Regulations: More Than Just the GVW

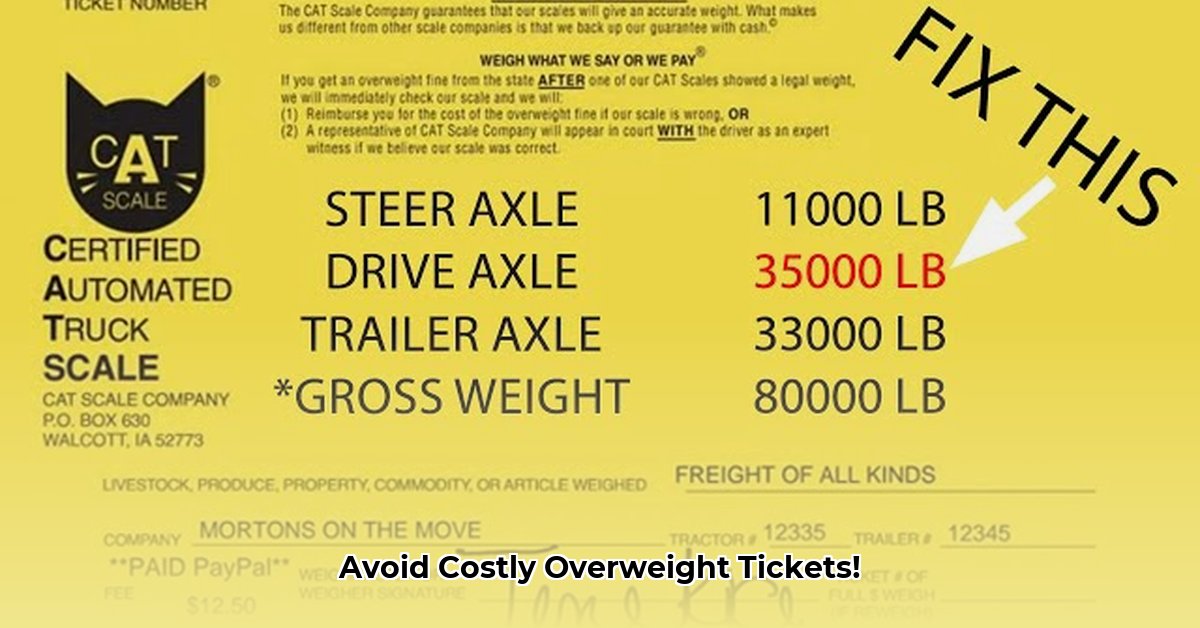

Many believe that staying under the 80,000-pound Gross Vehicle Weight (GVW) limit (for single trailers) is sufficient. However, exceeding the weight limit on any individual axle, regardless of the overall GVW, will result in a citation. This highlights the importance of understanding and managing axle weight distribution.

The Steer Axle: A Common Misconception

A common misconception is that the steer axle weight limit is always 12,000 pounds. The reality is far more nuanced. The permissible weight depends on several key factors, including the axle's design and rating, tire capacity, and – critically – individual state regulations. Legal limits can vary significantly, sometimes reaching as high as 20,000 pounds depending on the location and setup.

The Federal Bridge Formula: A Key Calculation

The Federal Bridge Formula (FBF) is a crucial element in determining legal weight limits. This formula calculates the maximum permissible weight based on the number and spacing of axles. It's not simply about the total weight; it considers the weight distribution across the axles. While the formula itself is complex, understanding its impact on allowable weight is essential for compliance. Closer axles can support more weight than widely spaced axles.

A Step-by-Step Guide to Axle Weight Management

Precise weight distribution is paramount to avoiding costly fines and ensuring safety. Follow these steps for effective axle weight management:

Regular Weigh-Ins: Utilize certified truck scales (often called CAT scales) for regular weigh-ins. This provides detailed weight data for each axle (steer axle, drive axles, and trailer tandems), allowing for early detection of potential issues. Proactive weighing can prevent costly violations.

Understanding the Weight Data: Compare the scale readings against the legal limits specific to your truck configuration and your planned route. Remember, state-specific regulations vary greatly. This analysis is critical for compliance.

Strategic Weight Shifting: If an axle is overloaded, carefully shift cargo to redistribute weight. Even minor adjustments can make a significant difference. Consider that even fuel weight can be shifted to maintain compliance. Proper weight shifting can often resolve overload issues.

Fifth Wheel Adjustment: The placement of the fifth wheel (the tractor-trailer connection) directly affects weight distribution. Minor adjustments can help redistribute weight, but only do so according to the manufacturer's instruction manual. Incorrect adjustments can damage your equipment.

Route Planning: Before beginning your journey, verify the specific weight limits for every state and even potentially specific areas along your route. State Department of Transportation (DOT) websites are valuable resources for this information. Planning prevents costly surprises and delays.

Maintain Detailed Records: Keep a detailed log of all weigh-ins and any adjustments made. This documentation will be crucial if inspected. Comprehensive records can protect you from unnecessary citations.

State-Specific Regulations: A Critical Consideration

Axle weight regulations vary significantly from state to state. What's legal in one state might be illegal in another. Always verify the specific regulations for each state your truck will traverse. These rules may also change, so regular reference to official guidelines is crucial for compliance.

Advanced Tools and Techniques

Several technologies can enhance weight management:

- Onboard Weighing Systems: These provide real-time weight data, allowing for immediate adjustments. Their use is growing in the industry.

- Route Planning Software: Sophisticated software can optimize routes to minimize the risk of weight limit violations by factoring axle weight restrictions.

- Comprehensive Driver Training: Thorough driver training on safe weight distribution empowers drivers to make informed decisions on the road.

Beyond the Fines: Safety as the Top Priority

Non-compliance with axle weight regulations results in more than just costly fines. Overloaded trucks are significantly more likely to be involved in accidents, endangering drivers and the public. Prioritizing safety through proper weight management is essential for responsible trucking operations.

At-A-Glance Axle Weight Information

| Axle Type | Typical Weight Range (lbs) | Important Considerations |

|---|---|---|

| Steer Axle | 12,000 – 20,000 | Highly variable, depends on state laws, axle rating, and tires. |

| Drive Axles | Varies | Weight distribution depends heavily on your specific truck's setup. |

| Trailer Tandems | Varies | Cargo distribution is critical; this greatly affects total weight. |

Responsible weight management is not merely about avoiding fines; it’s a cornerstone of safe and efficient trucking practices. Prioritize safety and compliance to ensure smooth and legal operations.